Alternative Crafting Method

Exploring The World of Sublimation Embroidery

Introduction

Embroidery has long been revered for its artistry and ability to transform textiles into personalized works of art. In recent years, the integration of sublimation printing with traditional embroidery techniques has revolutionized the industry, offering crafters and businesses unprecedented creative possibilities. This hybrid approach combines the meticulous craftsmanship of embroidery with the vibrant, full color capabilities of sublimation, resulting in products that are not only visually stunning but also durable and highly customizable.

In this article, we delve into the intricate world of sublimation embroidery, exploring its techniques, benefits, and cost dynamics. From selecting the right materials and optimizing design integration to mastering heat press techniques and exploring cost comparisons, we provide a comprehensive guide to help you navigate and leverage the strengths of this innovative textile crafting method. Whether you’re a seasoned artisan looking to expand your repertoire or a business seeking to differentiate your offerings in a competitive market, understanding the nuances of sublimation embroidery will empower you to elevate your creations with sophistication and style.

Join us as we unravel the art and science behind sublimation embroidery, uncovering its potential to redefine modern textile customization and inspire a new wave of creative expression.

The Origins and Evolution of Sublimation Embroidery

Sublimation embroidery represents a significant evolution in the realm of textile crafting, blending the traditional artistry of embroidery with the innovative capabilities of sublimation printing. Historically, embroidery has deep roots dating back thousands of years, where it served not only as a decorative technique but also as a means of storytelling and cultural expression across various civilizations.

In contrast, sublimation printing emerged more recently, gaining prominence in the latter half of the 20th century with advancements in digital printing technologies. Initially used primarily for transferring designs onto flat surfaces like paper and ceramics, sublimation gradually found its way into the textile industry due to its ability to produce vibrant, durable prints on polyester fabrics.

The convergence of these two techniques, embroidery and sublimation, arose from a desire to overcome the limitations of traditional embroidery, particularly in terms of color reproduction and design complexity. Embroidery, with its tactile richness and dimensional quality, provided a natural canvas for sublimation prints to enhance and complement.

This combination not only expanded the creative possibilities for artisans and designers but also catered to evolving consumer preferences for personalized and visually striking textiles. As technology advanced, so did the integration of embroidery machines capable of precise stitching with sublimation printers capable of reproducing intricate designs with vivid colors.

Today, sublimation embroidery stands as a testament to the seamless fusion of craftsmanship and innovation, offering limitless potential for creating bespoke apparel, home décor, and promotional items that blend the best of both worlds in textile artistry.

The Process of Creating Machine Embroidered Items

Embroidery is a meticulous craft that combines digital precision with artisanal skill. From design creation to final touches, each step plays a crucial role in producing beautifully embroidered items that stand out for their quality and craftsmanship.

• Design Creation

Design creation is where the journey begins. Using specialized embroidery software, crafters meticulously craft digital patterns that guide the embroidery machine’s movements. This software allows for precise control over every stitch and detail, enabling the translation of intricate designs onto fabric. Designers manipulate elements such as stitch types, densities, and color sequences to achieve desired textures and visual effects in their embroidery.

• Fabric Preparation

Fabric preparation is crucial to achieving high quality results. The selected fabric, typically polyester or a polyester blend for compatibility with sublimation, is hooped tightly to maintain stability during stitching. Proper hooping ensures the fabric remains taut and flat, minimizing the risk of puckering or misalignment. Stabilizers reinforce the fabric, preventing stretching or distortion under the pressure of embroidery stitches. This combination of hooping and stabilizing techniques lays the foundation for precise and professional looking outcomes.

• Embroidery Execution

Embroidery execution involves stitching the design onto the prepared fabric. Modern embroidery machines automate this process, following the digital pattern created earlier. They can execute various stitches, including satin, fill, and running stitches, depending on design requirements. Thread selection is crucial, from basic polyester threads to specialized metallic or variegated threads that add texture and visual interest. Attention to detail ensures each stitch is accurately placed, with thread tensions properly adjusted for uniformity and durability.

• Finalizing the Embroidered Item

Once embroidery is complete, the fabric is carefully removed from the hoop and excess stabilizer trimmed away. This final step ensures the item maintains its structural integrity and professional appearance. Additional finishing touches, such as washing to remove stabilizer residues or pressing to flatten fabric, may be necessary depending on project requirements. Proper handling and care preserve quality and longevity, preparing items for subsequent embellishments or enhancements like sublimation printing.

Adding Sublimation to Embroidered Items

Integrating sublimation printing with machine embroidery opens up a world of creative possibilities, merging the tactile richness of embroidery with the vibrant color saturation of sublimation. This innovative process allows crafters to enhance their embroidered designs with vivid, detailed prints, achieving a unique blend of texture and visual impact.

• Sublimation Design Creation

Sublimation design creation begins with digital software tailored for creating vibrant, detailed prints. Crafters can manipulate colors, gradients, and patterns to complement and enhance the embroidered motifs. The design should align precisely with the embroidered elements, ensuring a seamless integration of textures and colors. This step involves careful consideration of design placement and scale to achieve a balanced and visually appealing composition.

• Printing the Sublimation Design

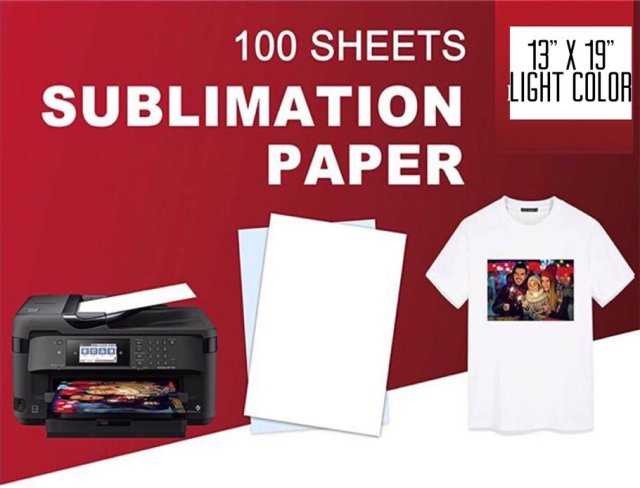

Printing is a critical step in the sublimation process, requiring specialized printers, sublimation inks, and transfer papers. The design is printed onto sublimation transfer paper using high quality, colorfast inks that will bond permanently with polyester fibers. It’s essential to calibrate the printer and select the appropriate settings to ensure accurate color reproduction and sharp detail in the final print. The printed design should mirror the digital artwork created earlier, capturing the nuances and vibrancy intended for the finished piece.

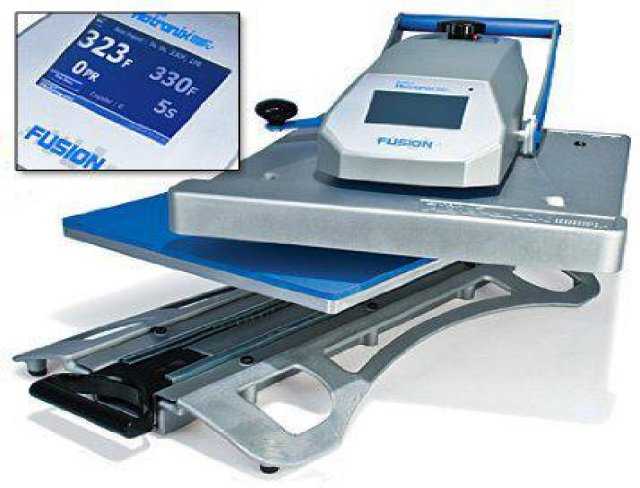

• Heat Press Transfer

The heat press transfer method is used to apply the sublimation print onto the embroidered fabric. This process involves carefully aligning the printed transfer paper with the embroidered item and applying heat and pressure using a heat press machine. The combination of heat and pressure causes the sublimation inks to transform into a gas, penetrating the polyester fibers and creating a permanent bond. Proper temperature and pressure settings are crucial to achieving vibrant, durable prints without compromising the integrity of the embroidery or fabric.

• Finishing Touches

Once the sublimation print is transferred, the item may undergo additional finishing touches to enhance its appearance and durability. This may include trimming any excess transfer paper, inspecting for alignment issues, and ensuring the overall quality of the print. Depending on the project requirements, post printing treatments such as washing to remove any residual ink or pressing to flatten the fabric may be necessary. Proper care and handling during this stage help preserve the integrity of the sublimation print and embroidered elements.

Incorporating sublimation printing into machine embroidery offers a versatile and creative approach to textile crafting. By combining the precision of embroidery with the vibrant color saturation of sublimation, crafters can produce unique and visually stunning pieces that stand out for their craftsmanship and artistic expression. Whether creating custom apparel, home décor, or promotional items, this innovative technique provides endless opportunities to explore and expand creative boundaries in textile design.

Benefits of Sublimation Embroidery

Sublimation embroidery stands at the forefront of textile innovation, merging the artistry of traditional embroidery with the dynamic capabilities of sublimation printing. This hybrid technique not only enhances the visual appeal and durability of textile products but also offers unprecedented flexibility in design and customization. By seamlessly integrating vibrant sublimation prints with intricate embroidery stitches, crafters and businesses can create unique, high quality items that captivate the senses and resonate with discerning audiences.

A: Enhanced Visual Appeal

Sublimation embroidery combines the tactile richness of traditional stitching with the vibrant, full color capabilities of sublimation printing, resulting in designs that are not only visually striking but also texturally engaging. This synergy allows for the reproduction of intricate details, gradients, and photographic images with exceptional clarity and depth of color.

B: Durability and Longevity

The chemical bonding of sublimation inks with polyester fibers during the heat transfer process ensures designs that are highly resistant to fading, cracking, and peeling, even after repeated wash cycles. Coupled with the structural reinforcement provided by embroidered stitches, sublimation embroidery offers durability that stands the test of time.

C: Customization and Personalization

Crafters and businesses benefit from unparalleled customization options with sublimation embroidery. From personalized gifts to branded merchandise, the versatility of this technique allows for the incorporation of unique designs, logos, and intricate graphics tailored to specific preferences and requirements.

D: Eco Friendly Process

In addition to its aesthetic and functional benefits, sublimation embroidery is recognized for its eco friendly credentials. Water based sublimation inks produce minimal waste and fewer emissions compared to traditional printing methods, aligning with sustainable practices in textile production.

E: Design Versatility and Flexibility

The seamless integration of embroidery stitches with sublimation prints enables limitless design possibilities. This hybrid approach empowers crafters to create multi dimensional patterns, textures, and effects that elevate the visual impact of textile products across various applications.

F: Market Differentiation and Branding

For businesses, sublimation embroidery serves as a powerful tool for market differentiation and brand identity. Customized merchandise featuring distinctive designs and corporate branding helps businesses stand out in competitive markets, enhancing brand visibility and customer engagement.

Sublimation embroidery represents a convergence of artistry and technology, offering unmatched versatility, durability, and aesthetic appeal in textile crafting. Whether creating bespoke apparel, personalized gifts, or promotional items, this innovative technique empowers crafters and businesses to achieve stunning results that captivate audiences and reinforce brand identity. Embracing sublimation embroidery opens doors to endless creative possibilities, ensuring that each textile creation stands out with unique style and enduring quality.

Techniques and Tips for Successful Sublimation Embroidery

Embarking on the journey of sublimation embroidery requires a nuanced understanding of both embroidery craftsmanship and sublimation printing techniques. This fusion of traditional stitching with vibrant sublimation prints offers endless creative possibilities but demands meticulous attention to detail and technical proficiency. Here, we delve into essential techniques and expert tips to help you achieve exceptional results in sublimation embroidery, from selecting the right materials to mastering heat press techniques and beyond.

1. Selecting the Right Materials

The foundation of successful sublimation embroidery begins with selecting compatible materials. Polyester and polyester blends are ideal choices due to their ability to withstand the heat and pressure required for sublimation transfer. When choosing embroidery threads, opt for polyester threads that can withstand the sublimation heat without compromising color vibrancy or durability. Understanding the compatibility between materials ensures that both the embroidery and sublimation components complement each other, resulting in cohesive and long lasting designs.

2. Optimizing Your Designs

Effective design preparation is crucial for seamless integration of embroidery and sublimation elements. Start by creating a digital design that carefully balances the embroidery motifs with the sublimation prints. Pay attention to design placement and scale to achieve a harmonious composition. Consider how colors and textures will interact between the embroidered stitches and sublimated areas to maximize visual impact. Utilize specialized embroidery software to visualize and refine the design before proceeding to production, ensuring precision and clarity in every detail.

3. Investing in Quality Equipment

Quality equipment plays a vital role in achieving consistent and professional results in sublimation embroidery. Invest in a high quality heat press machine with precise temperature and pressure controls suitable for sublimation transfers. Ensure that the embroidery machine is capable of handling intricate designs and polyester threads without compromising stitch quality. Quality equipment not only enhances production efficiency but also contributes to the durability and visual appeal of the final embroidered products.

4. Mastering Heat Press Techniques

Temperature and pressure control are critical during the sublimation process to achieve vibrant and durable prints. Use a heat press machine with precise temperature settings that align with the sublimation ink manufacturer’s recommendations. Adjust pressure settings according to the thickness and texture of the embroidered fabric to ensure even distribution of heat and ink penetration. Consistent temperature and pressure application throughout the heat transfer process prevent color discrepancies and ensure uniformity in print quality across the entire design area.

5. Practicing and Experimenting

Mastery of sublimation embroidery techniques comes with practice and experimentation. Start with small scale projects to familiarize yourself with material handling, design integration, and heat press techniques. Experiment with different embroidery stitches, thread colors, and sublimation ink combinations to discover unique effects and creative possibilities. Document your process and learn from each project to refine your skills and enhance your ability to produce high quality sublimation embroidered items.

6. Quality Assurance and Testing

Prioritize quality assurance and testing throughout the sublimation embroidery process to maintain consistent output and customer satisfaction. Conduct thorough testing on sample fabrics to evaluate color accuracy, print clarity, and durability before full scale production. Monitor heat press settings, thread tensions, and ink saturation levels during production to identify and address potential issues promptly. Implement quality control measures to inspect finished products for adherence to design specifications and overall quality standards, ensuring each piece meets or exceeds expectations.

Mastering the techniques and tips for successful sublimation embroidery requires a blend of technical expertise, creative vision, and meticulous attention to detail. By understanding material compatibility, optimizing design integration, investing in quality equipment, mastering heat press techniques, practicing and experimenting with different techniques, and implementing rigorous quality assurance measures, crafters and businesses can achieve exceptional results in combining embroidery craftsmanship with vibrant sublimation prints. Embrace these strategies to elevate your textile creations with distinctive style, durability, and visual impact.

Cost Comparison: Pure Embroidery vs. Embroidery with Sublimation

When considering the financial aspects of textile crafting, understanding the cost implications of different embroidery techniques is essential for crafters and businesses alike. Here, we conduct an extensive analysis comparing the costs associated with pure embroidery and embroidery combined with sublimation printing.

• Cost Components of Pure Embroidery

Pure embroidery involves the meticulous art of stitching designs directly onto fabric using specialized embroidery machines and threads. The primary cost components include:

♦ Material Costs: These encompass the expenses associated with embroidery threads and the base fabric. The choice of fabric, thread quality, and color selection significantly impacts the final aesthetic and durability of the embroidered product. Opting for high quality materials enhances the perceived value of the finished item but may entail higher upfront costs.

♦ Labor Costs: Labor costs in pure embroidery are influenced by several factors, such as the complexity and size of the design. Intricate designs necessitate more time and skilled labor to execute accurately, contributing to higher production costs. Skilled embroiderers with expertise in operating embroidery machines and ensuring precise stitching may command higher wages, reflecting the craftsmanship involved.

♦ Equipment Maintenance: Regular maintenance and servicing of embroidery machines are essential to uphold performance standards and prolong equipment lifespan. Costs associated with routine maintenance, including replacement of needles, lubrication, and occasional repairs, should be factored into the overall expense of pure embroidery.

• Cost Components of Embroidery with Sublimation

Embroidery with sublimation integrates traditional embroidery techniques with the vibrant, full color capabilities of sublimation printing. The cost components of this hybrid technique include:

♦ Material Costs: Similar to pure embroidery, material costs in embroidery with sublimation encompass polyester fabric, polyester threads, and sublimation inks. Polyester serves as the preferred substrate for sublimation printing due to its ability to absorb sublimation dyes effectively during the heat transfer process, resulting in vivid and long lasting prints.

♦ Sublimation Equipment: Significant initial investment is required for sublimation equipment, including a heat press machine and sublimation printer. These specialized tools are indispensable for achieving precise temperature and pressure control during the ink transfer process onto polyester fabric. While the upfront costs may be substantial, high quality sublimation equipment enhances production efficiency and ensures consistent print quality.

♦ Labor Costs: Labor costs in embroidery with sublimation encompass the time dedicated to designing, embroidering, and sublimating each item. Unlike pure embroidery, which focuses solely on stitching, embroidery with sublimation necessitates additional steps for creating digital artwork, printing with sublimation inks, and heat pressing onto fabric. Skilled labor is essential to manage these processes efficiently and ensure seamless integration of embroidery and sublimation techniques.

♦ Energy Consumption: Sublimation printing requires heat press machines to attain specific temperatures necessary for ink sublimation onto polyester fabric. Energy consumption costs should be considered, particularly during high volume production, to optimize operational expenses and maintain cost effectiveness.

• Comparative Analysis

To determine the cost effectiveness of each technique, consider the following factors:

♦ Initial Investment: Embroidery with sublimation entails a higher initial investment in equipment compared to pure embroidery. However, this upfront cost empowers crafters and businesses to broaden their product offerings and cater to diverse customer preferences for personalized, multi colored designs.

♦ Production Efficiency: Pure embroidery may offer simplicity in its production workflow, requiring fewer procedural steps compared to embroidery with sublimation. However, efficiency gains in sublimation printing, such as swift color application and enhanced customization capabilities, can offset higher initial costs over time by reducing labor intensive processes and increasing production capacity.

♦ Market Demand and Pricing: Evaluate market demand for customized and vibrant designs that underscore the benefits of sublimation embroidery. Consumers increasingly favor personalized products that reflect individual tastes and brand identity, driving higher pricing and customer loyalty. Embroidery with sublimation empowers crafters and businesses to capitalize on these trends by offering distinctive, visually captivating products that stand out in competitive markets.

• Long Term Considerations

Long term cost considerations encompass:

♦ Quality and Durability: Sublimation embroidery excels in color retention and durability compared to traditional printing methods. The chemical bonding of sublimation inks with polyester fibers ensures prints that resist fading, cracking, and peeling, preserving product integrity over prolonged use. Enhanced durability and quality can justify initial investment costs by minimizing the need for frequent replacements or refurbishments.

♦ Customization and Versatility: The versatility of sublimation embroidery enables limitless design possibilities, encompassing intricate patterns, photographic images, and vibrant color gradients. Crafters and businesses can accommodate diverse customer preferences and seasonal trends by offering customizable products that resonate with target audiences. Augmented customization capabilities enhance customer satisfaction and repeat business, heightening overall profitability and reinforcing brand reputation.

The cost comparison between pure embroidery and embroidery with sublimation is multifaceted and necessitates thoughtful evaluation of initial investments, production efficiencies, market dynamics, and long term benefits. While pure embroidery may underscore simplicity and lower upfront costs, embroidery with sublimation amplifies creative boundaries and elevates product appeal through vibrant, enduring prints. Crafters and businesses should strategically weigh these factors to determine the most cost effective approach that aligns with their production objectives, market strategy, and commitment to delivering superior, personalized products.

Conclusion

Both pure embroidery and embroidery combined with sublimation offer distinct advantages depending on your creative goals and business strategy. Pure embroidery, with its simplicity and lower initial costs, remains a cost effective choice for traditional designs and straightforward production workflows. On the other hand, integrating sublimation with embroidery enhances visual appeal, durability, and customization options, albeit at a slightly higher production cost.

When deciding between these methods, consider your project’s budget, timeline, and desired aesthetic impact. If you prioritize intricate designs, vibrant colors, and personalized products that stand out in competitive markets, embroidery with sublimation may offer the best return on investment. Conversely, if cost efficiency and streamlined production are paramount, pure embroidery provides a reliable option for achieving timeless elegance and craftsmanship.

By carefully assessing these factors and aligning them with your creative endeavors, you can confidently choose the embroidery technique that best suits your needs, ensuring exceptional quality and customer satisfaction in your textile creations.

Now that you have read through this article, feel free to SHOP for products we have created. If you are looking for something special which isn’t in our store, feel free to contact us.